ترجمه این پست به زبان های دیگر نیز روی سایت هست:

English

English  Persian

Persian

Introduction of the glass furnace

Introduction of the glass furnace

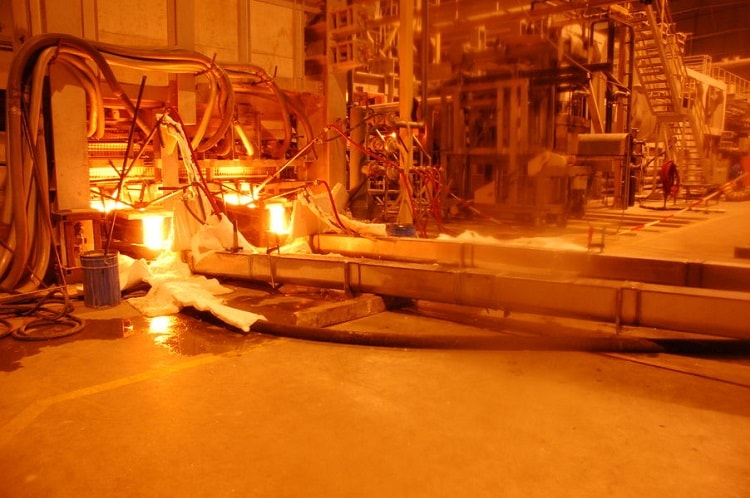

Glass furnaces are one of the most indispensable equipment of any glassmaking workshop. Glass furnaces are used to melt raw materials

Furnaces must be highly resistant to thermal and mechanical stresses from the environment.

Furnace walls should be thick and made of refractory and erosion resistant materials.

Also, furnace resistance to chemical corrosion is one of the essential factors.

Glass furnaces

The temperature of the glazing furnaces is on average between 1500 and 1600 degrees Celsius.

How to operate the glass furnace

Initially, the glass jar is heated to 1480 degrees Celsius in the oven.

Then glass melt. In this case, the viscosity of the material is so low that it cannot be used to make glass.

Therefore, the temperature of the furnace is lowered to 1260 degrees Celsius to reach a viscosity level that can be maintained in the tail tube and with which the glass is made.

Finally, the formed glass is gradually cooled to eliminate the risk of glass breaking.

After this step, the glass is ready for final payment.

Glass furnaces

Types of Glass furnaces

Generally, the Glass furnaces are divided into two categories: Shrub furnaces and Tank furnaces.

Shrub furnaces have less capacity than Tank furnaces.

For this reason, in high-production workshops, Tank furnaces are often used.

The capacity of the Tank furnaces is more than 10 cubic meters.

Sources:

MahjamGlass manufacturer of all kinds of mirror models.

Design from you, build from us.

You can decorate your home like a palace.